Block making machine

Short intervals, short downtimes, precise filling, simple and reliable operation – these are the foundations of successfull, higliy productive manufacturing.

There is no machine on the market to better fulfill these promise than our top model, the OMAG Tronic.

Mechanics and kinematics

- Heavy duty machine frame in solid welding construction

o prevention of cracking

- easy accessibility

o fast lock and unlocksystem

- automiatic quick Mould Change slide

o Mould sledge with triangular guide and hydraulic cylinder

o one man mould change

- Wearing plate for fillerbox table

Mixing and batching

- separate mixer for base and face mix

- Planetary fine & base mixer with skiphoist

o high quality mixing results

- Bucket conveyor transportation

o avoidance of excessive wear of the mixer

o avoidance of segregation

o avoidance of fast drying of the cement

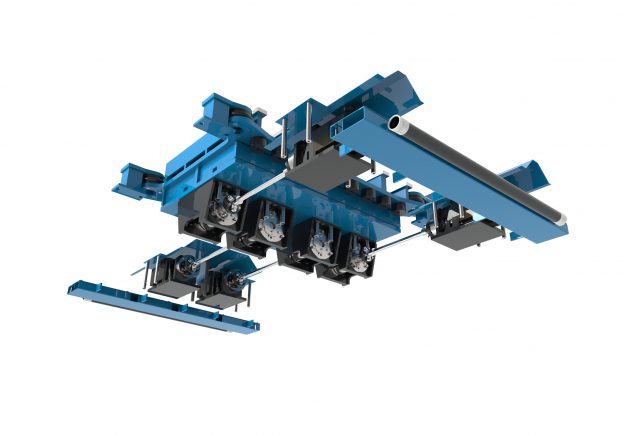

COLORMIX System

- The hoppers of Colormix System are filled with colored batches from the mixer

- The Colormix System moves excactly over the hoppers of the machine (by a frequency controlled drive and encoder)

- Each hopper is a weighing hopper

- Exactly dosing into the hopper by dosing roller

- The amount of concrete is adjustable

- Each hopper has 2 or 3 feeders

- Recipes on color, weight and feeder position make a absolute reproducibility possible

Technische Daten: Anzahl der Farbkübel: 3 Farbbetonmenge max.: 3 x 1200 kg Dosierleistung: 1 bis 28 l/s Fahrgeschwindigkeit: 0,1 – 0,8 m/s Spur Schiene: 1750 mm Radstand: 4425 mm Bauhöhe: 1600 mm Einlauf: 1250 x 1250 mm Auslaufbreite: 2 x 550 mm Eigengewicht: 3200 kg Andere Größen auf Anfrage

Vibrationsystem

The latest generation of vibration technology.

The highly dynamic servo amplifiers provide an integrated and fast control technique with further advantages

• maximum performance

• exact repetition of vibrations, also for vibration times less than 70 ms

• less waste through better compaction

• reduction of cycle times

• increasing output leads to a rising productivity of the plant

• energy savings

Your benefits:

- latest technology

- fast delivery

- 2 days for installation

- experienced Support

Finger car group

The Finger Car automatically transports the new products from the elevator to the curing chambers and after curing to the lowerator.

- Solid base frame in rugged welded construction

- 4 wheel and bearing assemblies with flanged wheel

- Turntable is electrically driven (optional)

- Electric locks secure the Transfer Car’s position at the rails

- Locating control is laser and provides high accuracy in steam

Cuber

The cuber automatically forms shipping cubes. The layers are transported from the de-palleting to the palleting station and – if necessary – rotated.

All 3 movement axles are electrically driven and are provided with digital path measurement devices to drive a distance and time optimized motion curve.