PRESSES made by OMAG

OMAG-Servopresse

The servo press is a testimony to the capacity for innovation of the OMAG special machine construction.

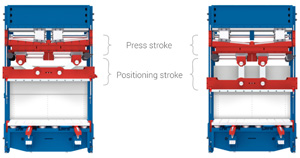

Consisting of two main components, the press stroke and the secondary positioning stroke, this press represents a system that has not existed

before.

Press stroke

The press stroke ensures the actual pressing force with a wedge system.

Through the use of electric drives and high-precision sensors, the force is exerted and held with the utmost precision.

Psitioning stroke,

The positioning stroke on the other hand,

consists of two independently movable

connecting rods, which enable a large, fast stroke.

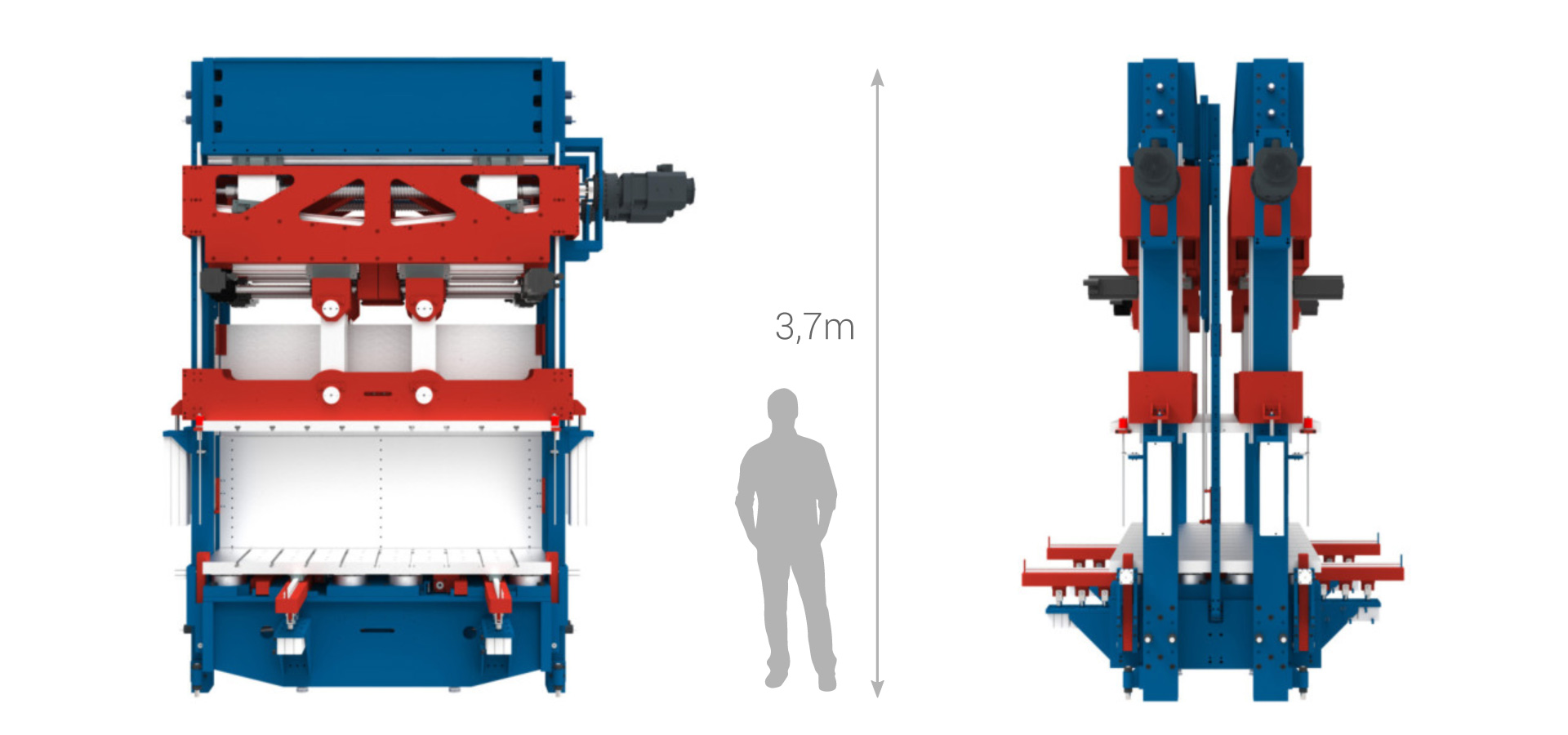

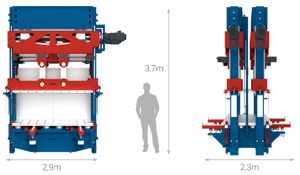

The illustration shown here is an ideal design for a double servo press.

Any dimensions and designs are possible.

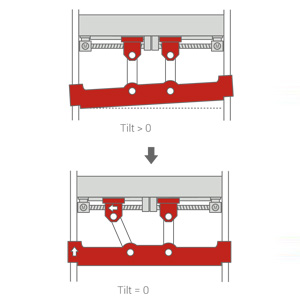

This press uses the individually movable connecting rods for an active plane parallelism control, which aligns the press head to a few hundredths of a millimeter exactly to the press table.

To do so, there is always a vertically positioned connecting rod, while the other one moves to ensure the plane parallelism. In addition, this principle can also be used to centre the centre of force on the press table.

Features

Very compact design

Variations with several presses are possible

Highly precise force and position control

Independently movable connecting rods

User-defined dimensioning

Plane parallelism control

Tilt adjustment

Specified tilting

Centre of force adjustment

Centre of force specification